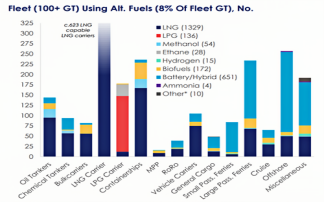

In 2025, the global new shipbuilding market continues the wave of green transformation, and the proportion of orders for alternative fuel vessels in the first two months has reached a historical high. China's shipbuilding industry holds a dominant position in the field of green ships. In February, it undertook 73.2% of the global orders for new alternative fuel vessels, continuously consolidating its leading position in the global shipbuilding industry.

According to the latest statistical data from Clarkson, among the total 123 new ship orders with a total deadweight of 6.8 million tons globally from January to February this year, as many as 70 vessels with a total deadweight of 5.1 million tons are alternative fuel vessels, accounting for 75.2%. This proportion exceeds the 48.4% for the whole of last year and is also higher than the 54.3% for the whole of 2022, which set a historical record at that time. Calculated by the order value, the total global investment in new shipbuilding from January to February is 13.8 billion US dollars, and the order value of alternative fuel vessels is 9.8 billion US dollars (approximately 71.13 billion yuan), a year-on-year decrease of 48%, and the proportion reaches 71.5%.

.jpg)

.jpg)